To know the position of the servomotor axis, LibreServo uses the AEAT-8800 16-bit encoder. This encoder replaces the potentiometer that the servomotors have and with it we get much more precision and allows the servomotor to rotate 360 degrees.

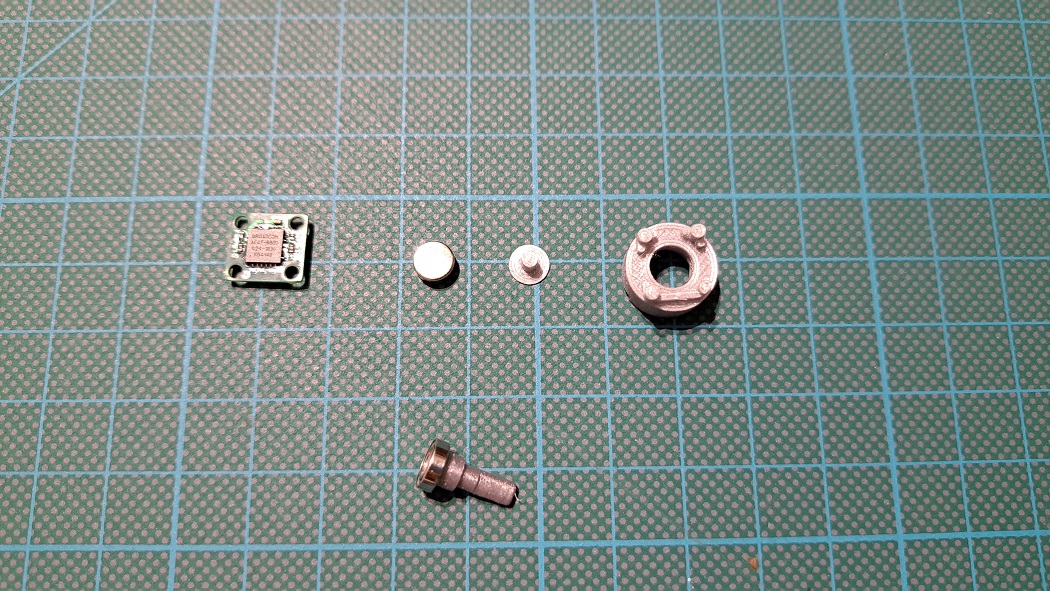

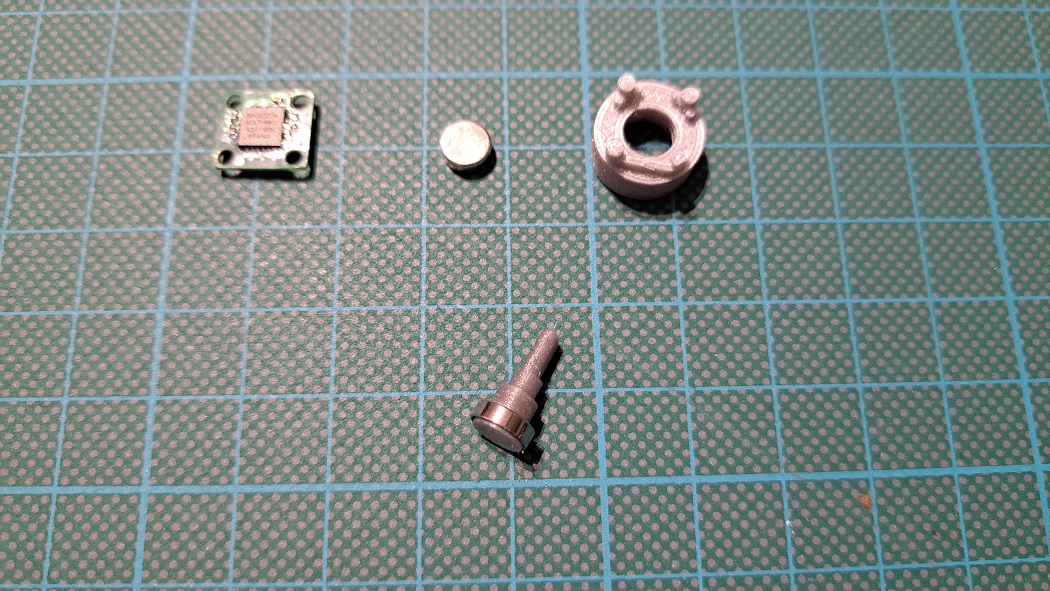

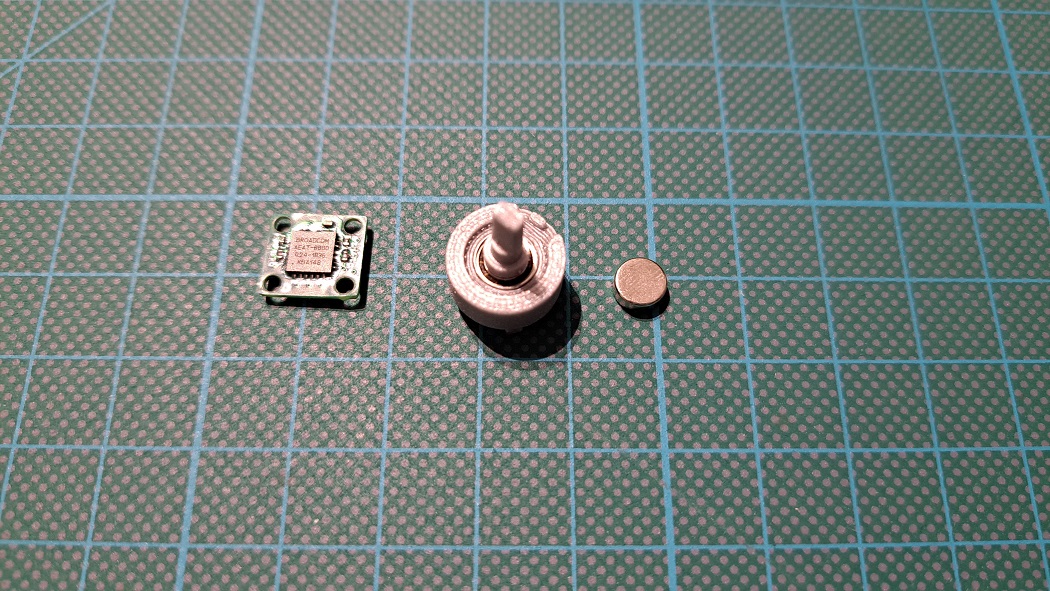

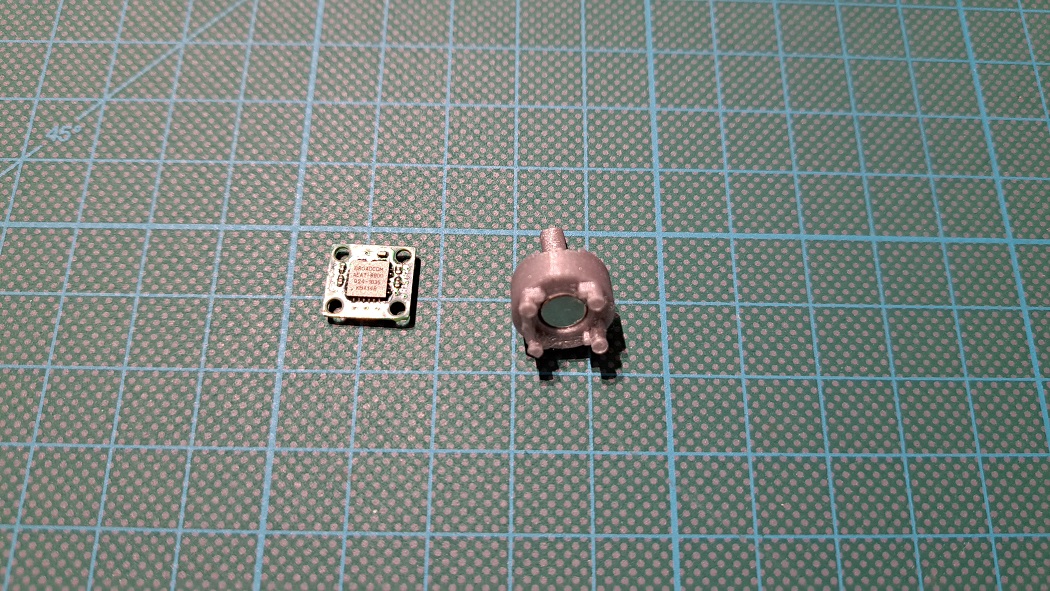

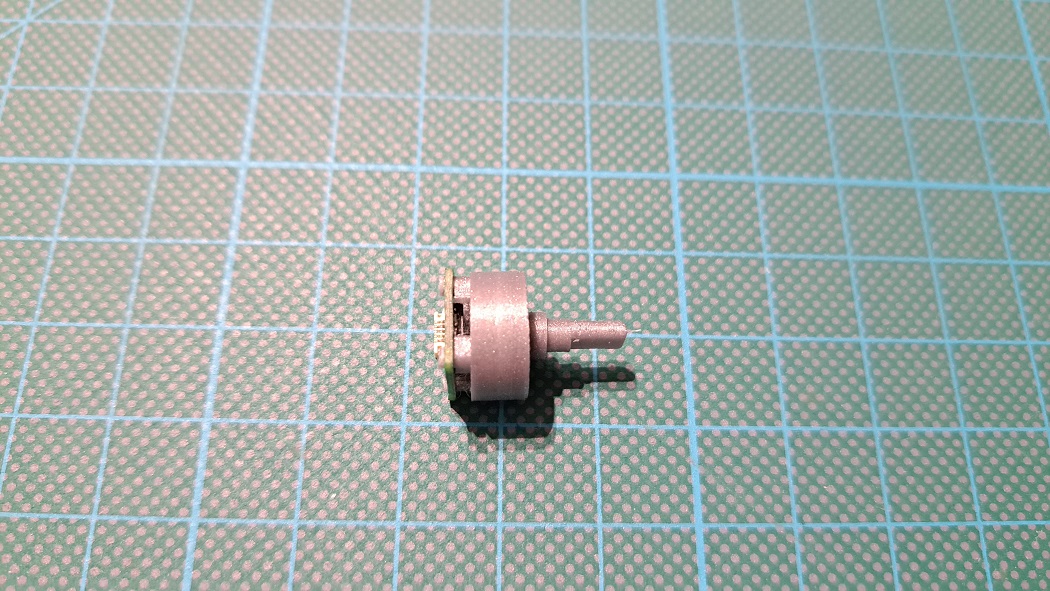

To achieve this, LibreServo makes use of a tiny 10.2x11.2 mm PCB to which a 3D printed part of the same size and shape as the original potentiometer is attached. This 3D printed part consists of 3 small parts, a 4x7x2mm bearing and a small 6x2.5mm diametrically magnetized magnet. Only a glue point is needed to fix the magnet. The rest of the parts, bearing and PCB are designed to be snap-fitted and fixed.

With the first release of the LibreServo software, the 3D parts have also been updated. The .stl is uploaded to the Libreservo github in the 3D folder. The parts are designed to be printed with 0.1mm layers.

The parts are: