LibreServo v2.3.1. Release Version

LibreServo v2.3.1. Release Version

LibreServo v2.3.1. Release Version

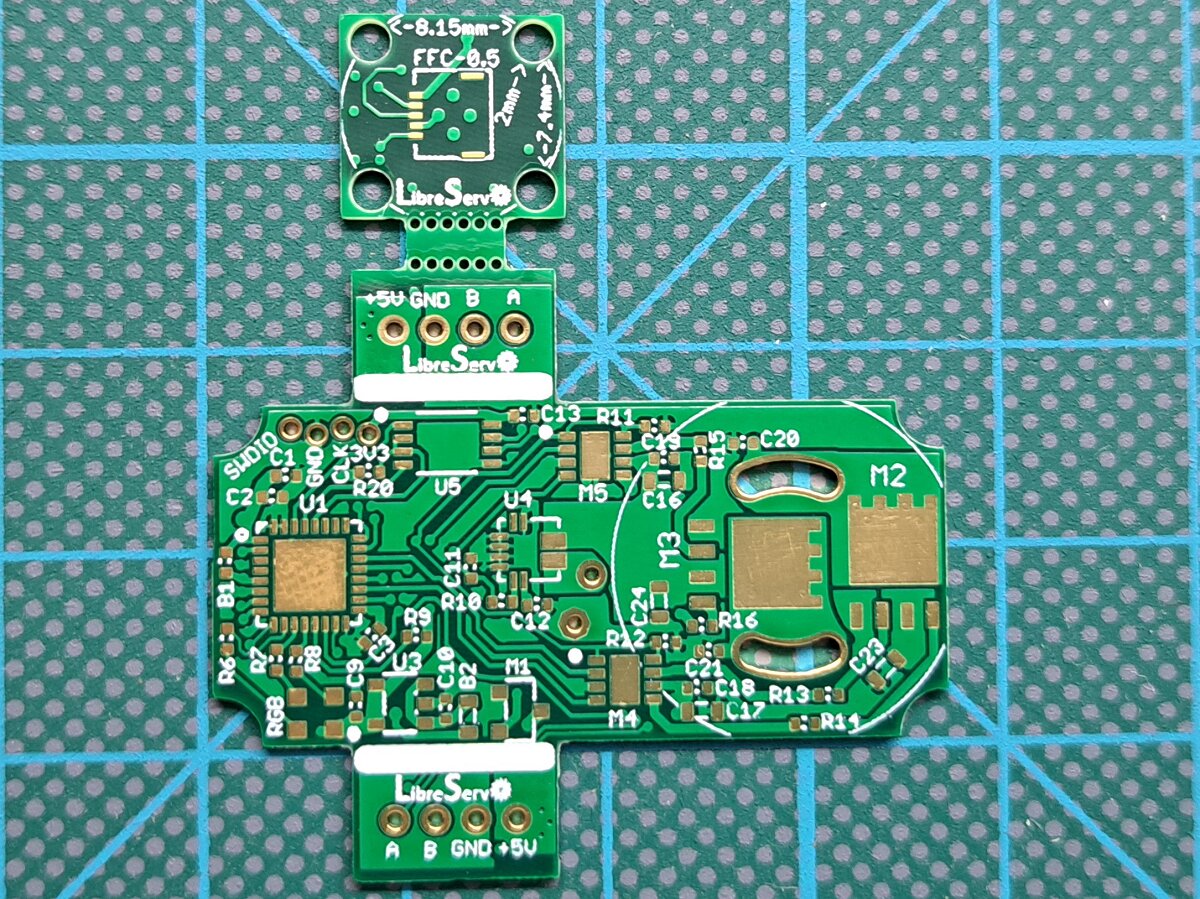

LibreServo has finally reached the first final Hardware release (version 2.3.1)!

It has been a long road and there is still a long road ahead, but now on the software side. LibreServo will not stop here and later on there will come new projects that make use of LibreServo, like a possible 3D biped robot, but all of that will come in the future and all of it will be announced here so let's stop the guessing and talk about the now.

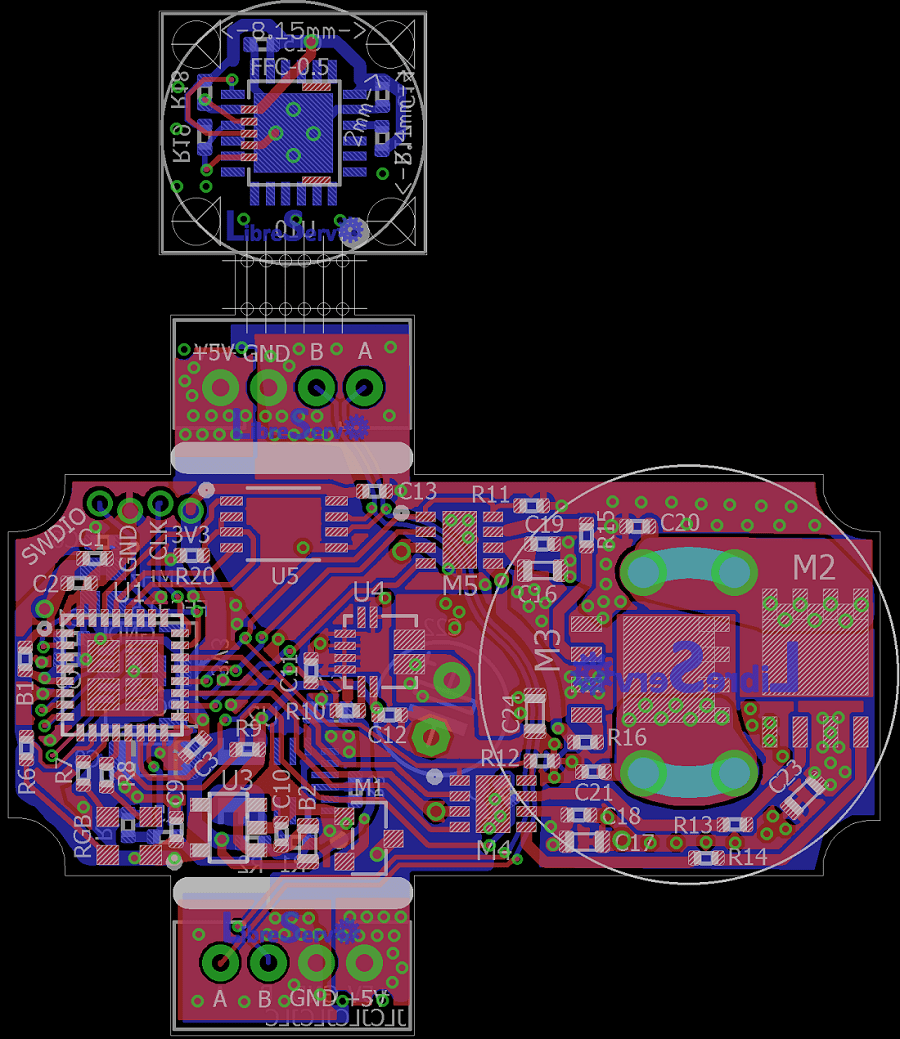

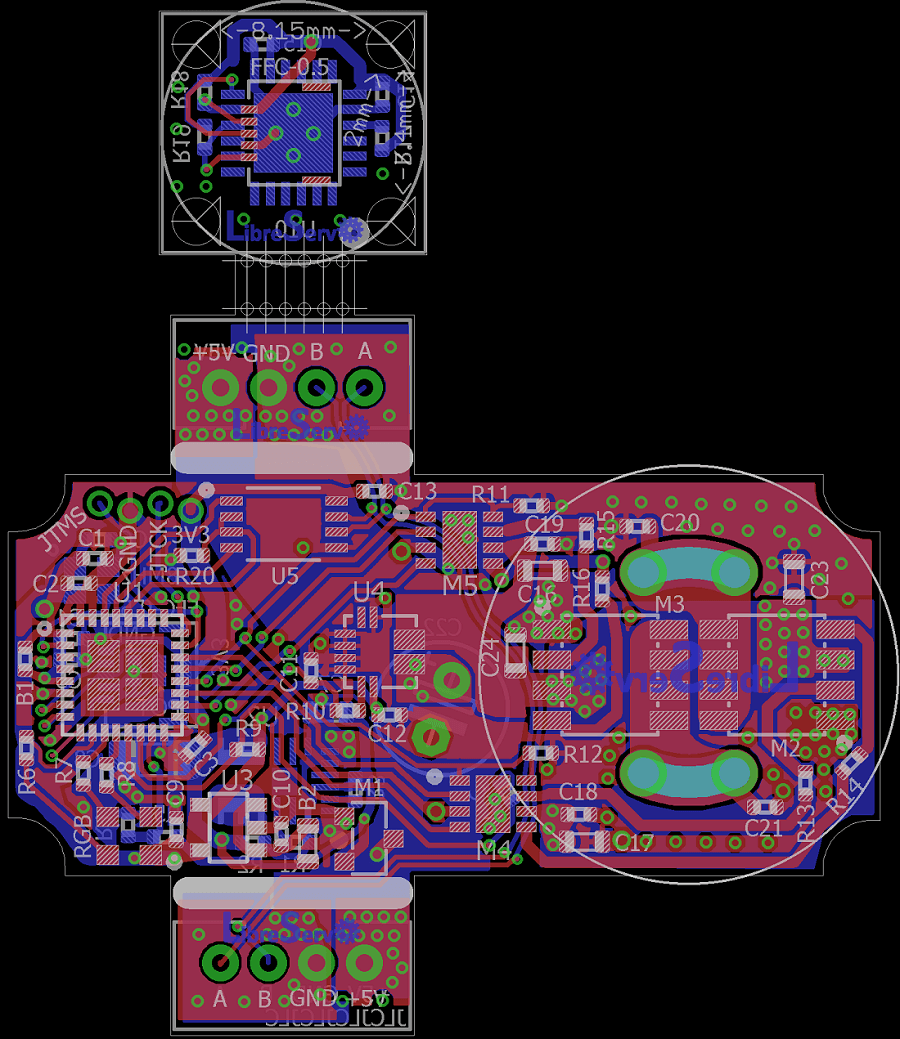

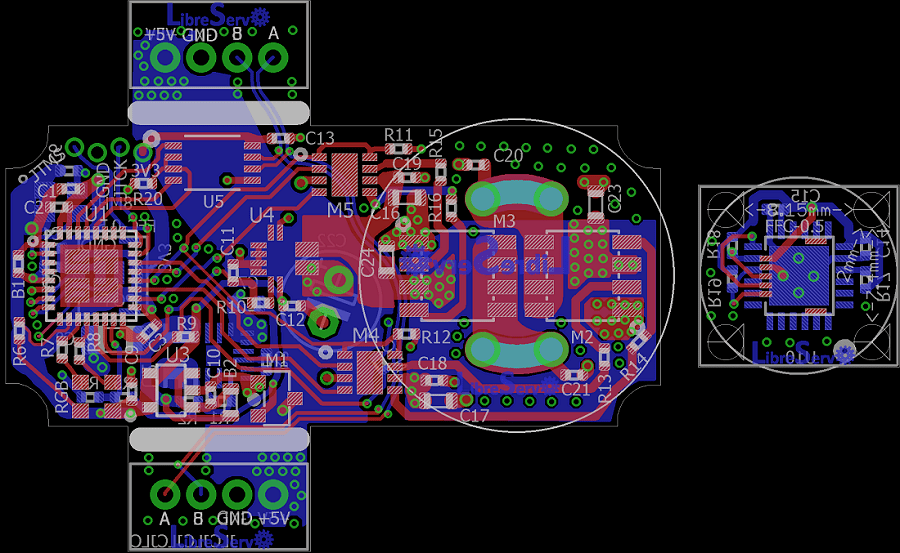

LibreServo v2.3 PCB

LibreServo v2.3 PCB

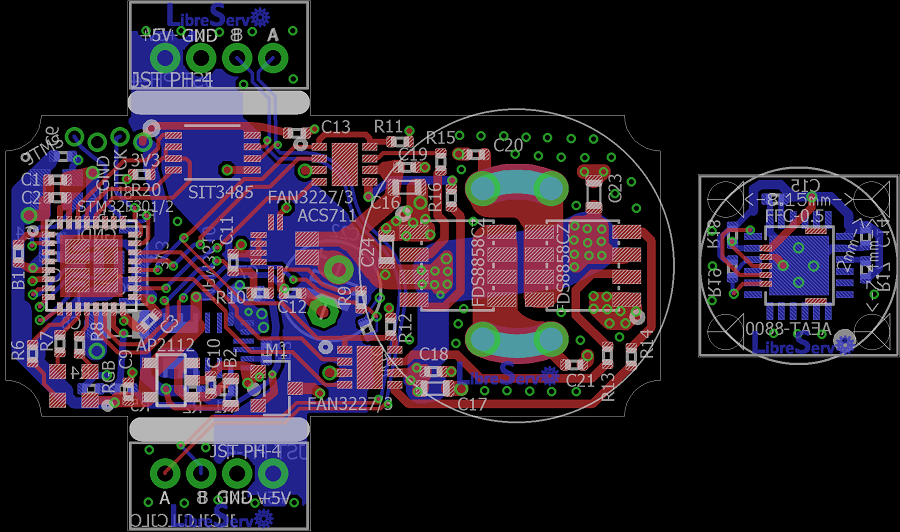

LibreServo v2.2 PCB

LibreServo v2.2 PCB

LibreServo v2.1 PCB

LibreServo v2.1 PCB

LibreServo v2 PCB

LibreServo v2 PCB