How to properly tune a PID

There are hundreds of guides on the Internet on how to adjust a PID and they can all be summarized in the following simple steps:

- Set KD and KI to zero and increase KP until the system corrects the error and starts oscillating. That would be the maximum KP

- Increase KD until the KP oscillation stops.

- Increase KI slightly so that the system fully corrects the error.

They seem like three simple and quick steps, but the reality is that in the end it becomes a sort of trying to guess the constants and after hundreds of tests and hours, if you are lucky, you get a relatively stable PID. It is a rather cumbersome task that rarely achieves a completely satisfactory result.

Let's forget about all that and try to obtain KP and KD mathematically.

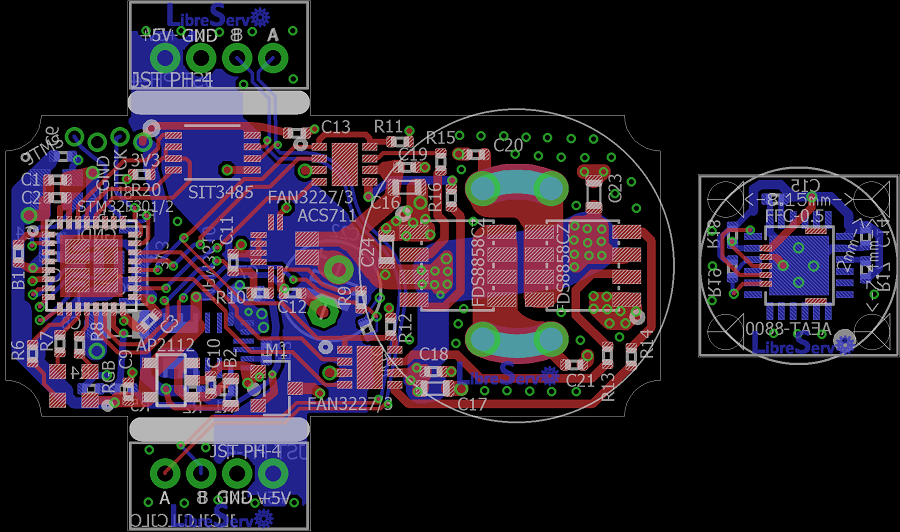

LibreServo v2 PCB

LibreServo v2 PCB

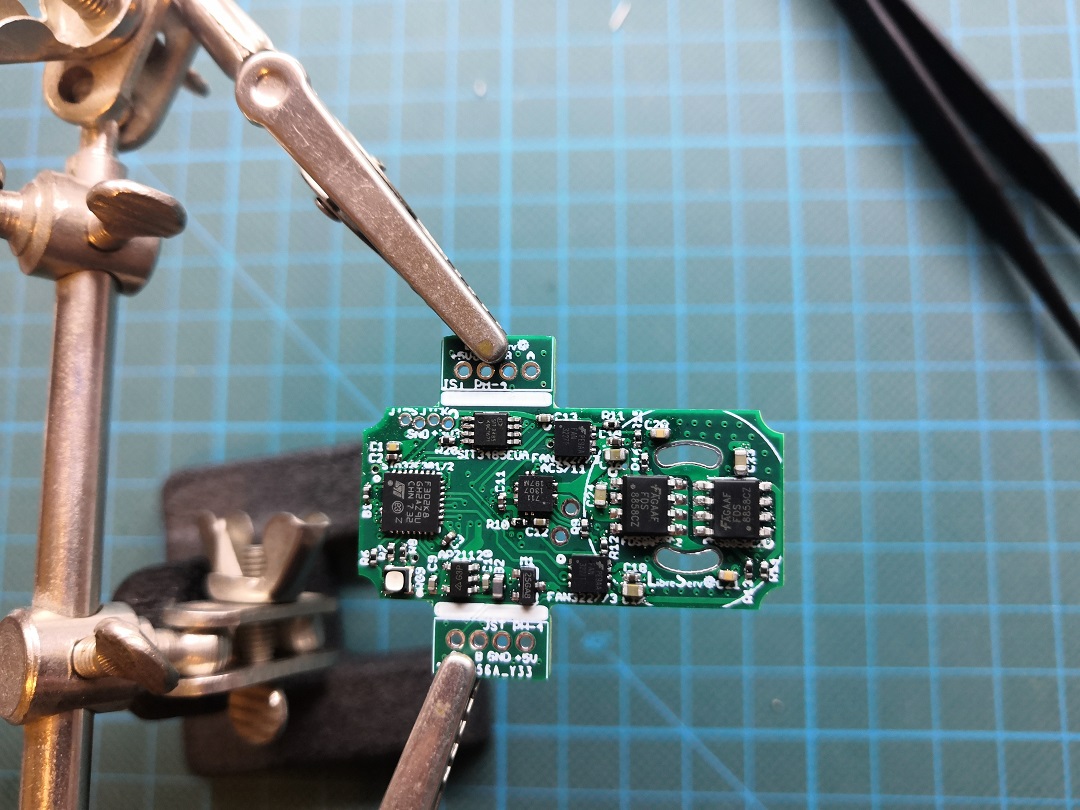

Soldering the first LibreServo v2

Soldering the first LibreServo v2